The project brief

A business start-up approached me to design a handheld electric foam cutting machine for sculptors. Having evaluated their project brief, I ran through various concepts with them that included the idea of a cordless foam cutter that was liked by all very much. Cables are usually a hindrance as they take up space, restrict movement and create a mess. The only issue was ensuring adequate power as foam cutters typically need to generate enough heat to melt the foam around them.

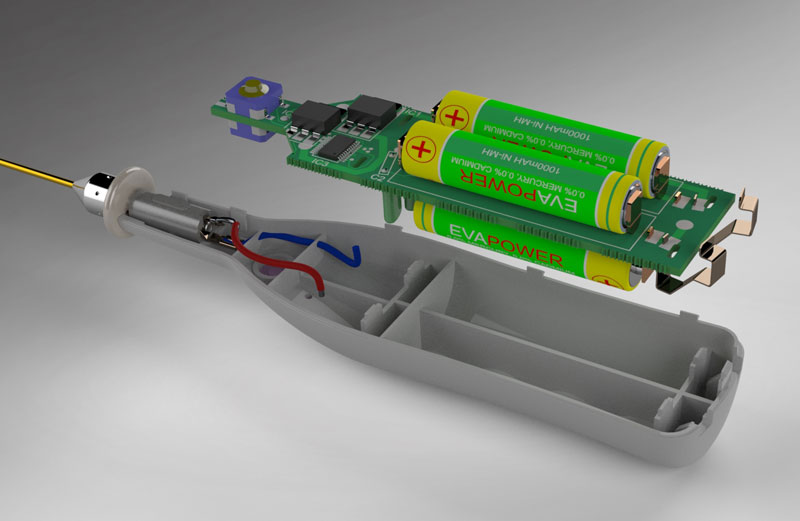

Working with a team of electronic engineers, we came up with a charging solution that could charge a small bank of batteries within ten minutes. Using four AA-sized NiMH batteries (to keep the unit as compact as possible), we were able to provide around half an hour of intermittent foam cutter use from a single charge. The time was deemed adequate for users, particularly considering charging the unit would only take ten minutes.

I kept the cutter design as simple as possible to allow good flexibility of movement during use. Individual heads that were easy to remove had to be designed with low energy, high-efficiency heating elements. It was a challenge integrating heat resistant materials around the head interface while maintaining the interchangeable aspect.

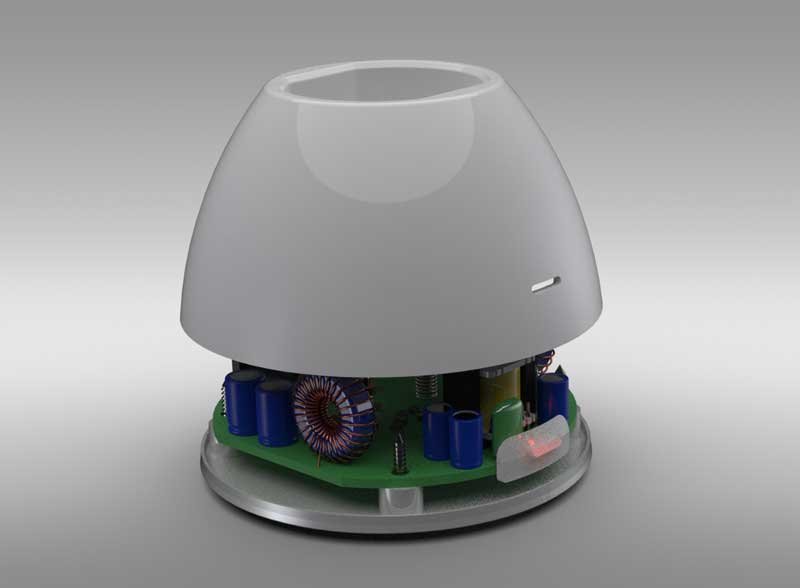

The charging base of the unit contains an efficient high current 'switch mode power supply' that derives its power straight from a UK mains socket. Only one small tactile switch is integrated into the handheld unit, powering it on or off with two modes of operation – intermittent switching and latching. The charging base has no switches or controls, other than a power indicator light illuminating red when charging and green when the unit is fully charged and ready. Users favoured this simplistic design.